According to the 2009/10 Statistics from the New Zealand Fire Service electrical fires accounted for 24% of recorded incidents for fires in structures. Of those electrical fires 40% originated in a switchboard or meter box.

Many insurance companies are now insisting that a thermographic inspection be completed as a means of assessing the insurance risk prior to formalising a policy. The little money invested now on regular inspections could save tens of thousands of dollars down the track in equipment replacement and lost production.

Most surveys are done annually. However, it really depends on the type of business, the age of the plant and equipment plus the risk factor. The inspection needs to occur when all plant and equipment is being used to capacity in order to show equipment that may be deteriorating under full load conditions.

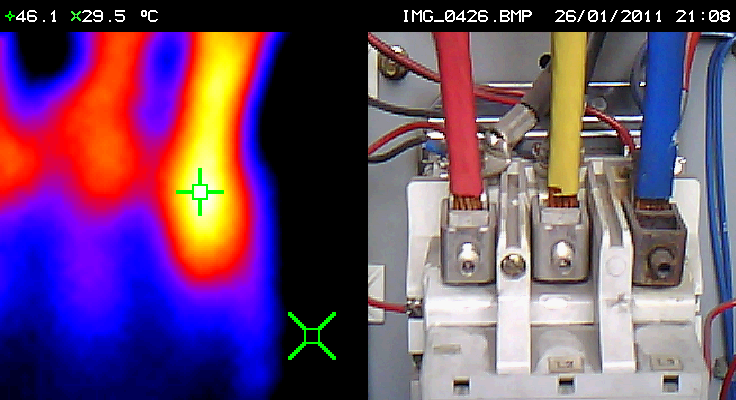

Thermographic inspectionis not simply a matter of pointing an infrared camera at an object and displaying the resulting image in a report. Electrical engineering knowledge is required to know if the recorded temperatures are within normal ranges. Applying knowledge of circuit design and loading.

As Master Electricians we have many years of experience in thermographic inspection. J N Wilson Electro Services has the specialist knowledge to complete the inspection and report writing process. Your report will highlight the significant equipment hotspots so that you can see at a glance what requires your attention.

During the electrical inspection, we will carefully and precisely measure the temperature and condition of your electrical system. This inspection will not only reduces the risk of a serious electrical incident, but also helps improve system performance. Excess heat in electrical systems is a serious warning sign, and detecting these issues before they become problems is only possible with a thermal camera and a compedent inspector.

© Wilson Electro Services . All Rights Reserved. Web Design Canterbury